Synthetic polymer fibres

-

Introduction

Synthetic polymer fibres

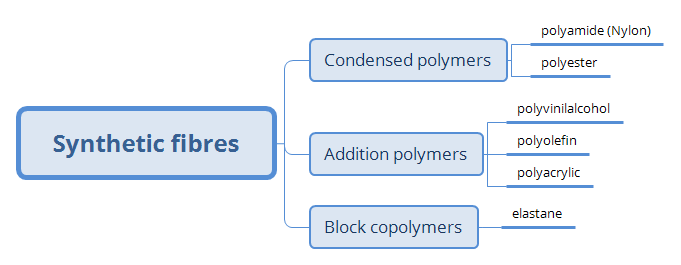

Synthetic polymer fibres can be classified based on the general chemical mechanism used for building the linear polymers.

Fibre type Fibre composition Cross-section appearance Polyester Poly(ethylene-terephthalate) Depends on spinneret Nylon polyamide Depends on spinneret Acrylic Poly-acrylonitrile Depends on spinning conditions Polypropylene polypropylene Depends on spinneret Elastane polyurethane fibrillar QuestionsClick on the headings below for more information

Polyester-PES

- Variants – PET most common

- Methylene groups, Carboxyl groups, ester link, benzen rings

- DP 115-140

- 65% Crystalline 35% amorphous

- Highly oriented in amorphous areas

- Very useful – most used synthetic fibre

Polyamide-PA

- First synthetic fibre 1939, DuPont

- Parachutes, shirts, underwear, carpets, outdoor clothing

- Today substituted by PES/Cotton in shirts, underwear etc.

-

Nylon

- Amide groups

- Degree of polymerisation (DP): 50-80

- Zig-zag molecule chain, high crystalline and orientation

- 65-85% crystalline 15-35% amorphous

- Nylon 6 (PA6) and Nylon 6.6 (PA6.6)

Acrylic-PAN

- 1950 DuPont

- Homo-polymer – Compact structure – Bikryl®

- Co-Polymer open structure – Acrilan®

- DP ~ 1000

- Wet or Dry spinning, no melt spinning

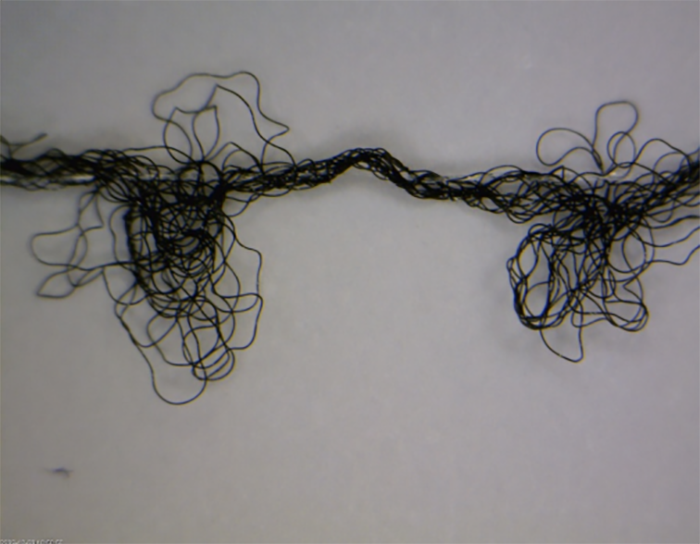

Elastane-EL

- 1959 – DuPont

- Elastomeric fibre

- Hard and soft segments

- Stretched repeatedly return to original length

- Blended with other fibres

- Spandex® Lycra®

×

Lycra®

Trevira expand

Pair the following international fibre abbreviations with the correct generic fibre name:

PAN ?

- Polyester

- Acrylic

- Polyamide

- Lyocell

PES ?

- Polyester

- Acrylic

- Polyamide

- Lyocell

PA ?

- Polyester

- Acrylic

- Polyamide

- Lyocell

CLY ?

- Polyester

- Acrylic

- Polyamide

- Lyocell

The shape and size (cross section) of manufactured fibres are determined by:

- It's elongation properties.

- The holes in the spinnerets.

- The amount of crimp in the fibre.

- It's origin.

Fine streams of chemical solutions are pressed through the holes in the spinneret and hardened into continuous strands of filament fibres.

A triangular shaped fibre will feel harsher and hide soil better than a round fibre.

- True

- False

Fibre cross-section form and length surface determines the fibrers texture, bulk, hand, luster, soil retention properties, etc.

What changes in the spinneret would have to be done for the following to occur:

Thicker filament fibres?

- Larger holes

- Smaller holes

- More holes

- Less holes

- Change shape of holes

Produce more fibres?

- Larger holes

- Smaller holes

- More holes

- Less holes

- Change shape of holes

Change cross-section shape ?

- Larger holes

- Smaller holes

- More holes

- Less holes

- Change shape of holes

-

Project

Contact

This resource was developed as part of an Erasmus+ project, funded with support from the European Commission under grant agreement 2016-1-SE01-KA203-22064.

The project was a collaboration between:

- The University of Borås, Sweden

- The University of the Highlands and Islands, Scotland

- The University of Alcalá, Spain

- Digital Connections, Scotland

This resource has been released under Creative Commons license CC-BY-SA 4.0.

Disclaimer

If you would like more information on this resource please contact:

- Academic content – The University of Boras (www.hb.se)

- Technical resource development – The University of the Highlands and Islands Educational Development Unit - EDU (edu@uhi.ac.uk)

Except where otherwise noted, this website is licensed under Creative Commons license CC-BY-SA 4.0. All images used under permission remain the copyright of the license holder.

Download a copy of this resource in PDF format.

You can also print individual pages by printing directly from the browser.

-