Dyeing machinery and processes

The dyeing process can be carried out in different modes:

- Continuous

- Semi-continuous

- Discontinuous (batch)

The choice of dyeing equipment depends on the type of fabric (woven, nonwoven and knitted), fibre (natural or synthetic) and the chosen class of dye.

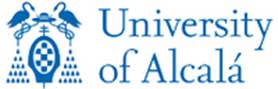

Continuous dyeing

- Feeding the textile substrates continuously into a relatively small pad bath containing the dyestuff and auxiliaries.

- Aiming high production.

- Consists of dye application, dye fixation with heat or chemicals and finally washing.

- Most suitable for woven fabrics.

- The machine's length controls the speed.

Continuous dyeing process © University of Borås

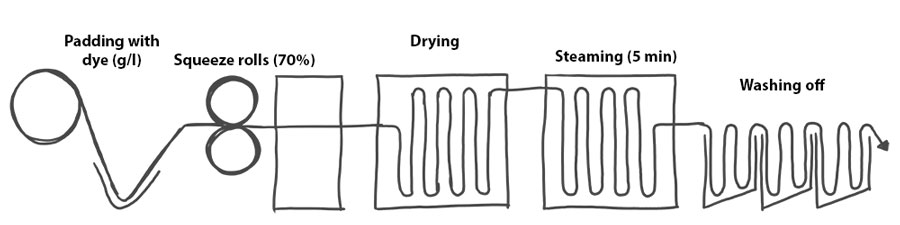

Semi-continuous dyeing

- Consists of pad batch, pad-jig and pad-roll

- Cotton, linen and viscose

- Reactive dyes

Semi-continuous dyeing process © University of Borås

Batch dyeing process (Exhaust dyeing)

- Most common method used for dyeing of textile materials.

- All types of fibre.

- All dye classes.

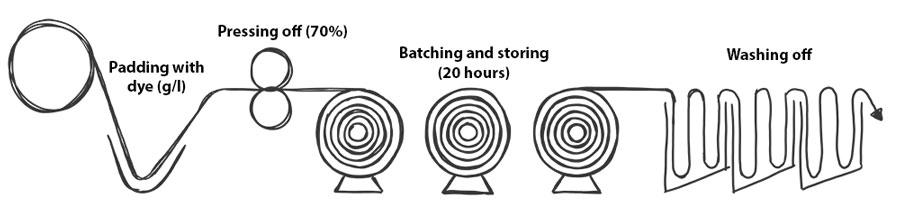

Jigger © University of Borås

Jet dyeing machine © University of Borås