Scouring

Scouring is the process of removing all undesirable impurities such as foreign matter, soil or processing aids (waxes, lubricants, etc.) from fabric/yarn prior to dyeing or finishing. This pretreatment is an important stage, especially for natural fibres which have a significant presence of natural impurities. Conventionally, scouring involves the use of wetting agents (surfactant), Emulsifiers (Non-ionic surfactants) and alkaline solutions to remove hydrophobic components from the primary wall. Synthetic fibres may need only a mild detergent scour.

Scouring will make fabric sufficiently hydrophilic, remove impurities, increase absorbency and produce clean surface for next processes.

Methods of scouring

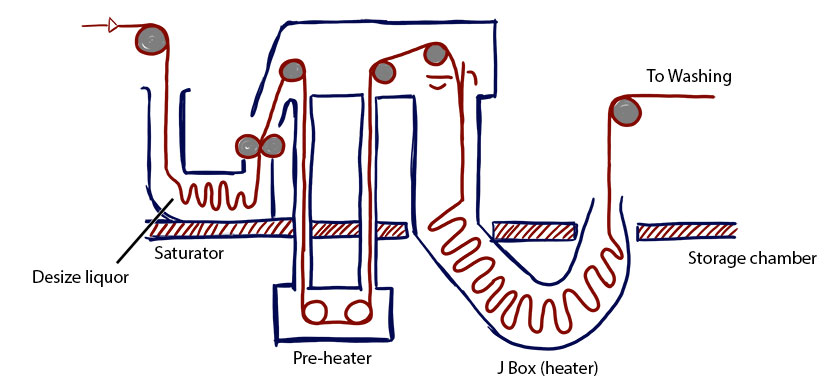

Continuous method: J-BOX (see graphic)

- It is called J-BOX process since the scouring vessel looks like “J”.

- Feeding fabric from one end and coming out the scoured fabric from the other end.

- Impregnation box (Impregnation temperature: 70-80°C, impregnation time: 40-90 sec).

- Pre-heating (at 90-100°C for 30 sec).

- J-BOX (1-4 hours at 100°C).

- Washing unit.

Discontinuous method: Kier Boiling (Pressure kier)

- Removal of impurities by alkaline boiling under pressure.

- Very good removal of impurities.

© University of the Highlands and Islands