Printing

Printing can be described as localised dyeing in different patterns on a substrate.

There are several basic approaches to print colour on a fabric. Click on each item below for more information:

-

Direct printing

Applying the printing paste directly to the fabric surface with desired pattern.

Direct printing on fabric (YouTube, 3:40)

-

Discharge printing

Overprinting a plain dyed fabric with a discharge paste which changes or destroys the colour in the designed areas

Discharge printing (YouTube, 2:07)

Printing with discharge print paste

© University of Borås -

Resist printing

Printing with a resist paste and passing the fabric through a subsequent dyeing process (the printed area is not coloured).

Resist printing (YouTube, 1:38)

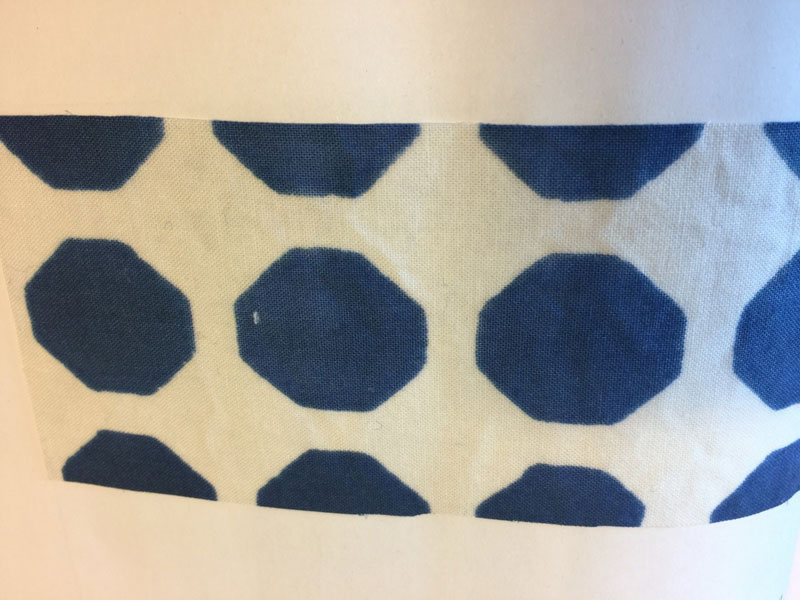

Resist print

© University of Borås -

Transfer printing

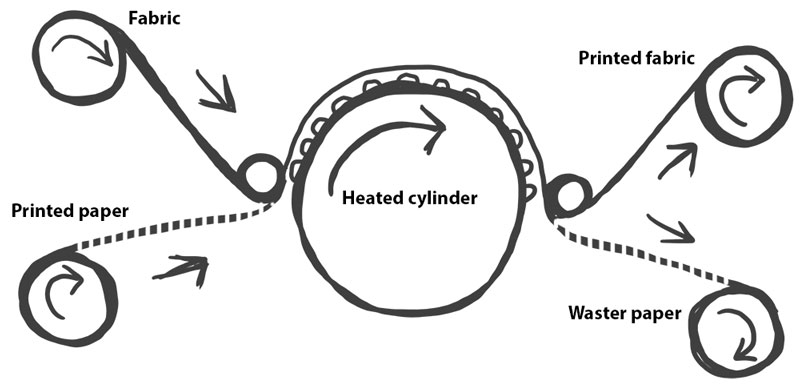

Literally moving a design from one surface to another. Printing the design on to a special type of paper and transferring the pattern to the fabric with the help of a heated calendar.

Heat transfer printing

© University of Borås

Heat transfer printing

© University of Borås

Transfer printing

© University of Borås -

Flock printing

Flock printing or flocking is a printing process in which glue is printed on the fabric and then the fibre flock is applied on the adhesive-coated surface.

Flock printing (YouTube, 2:31)

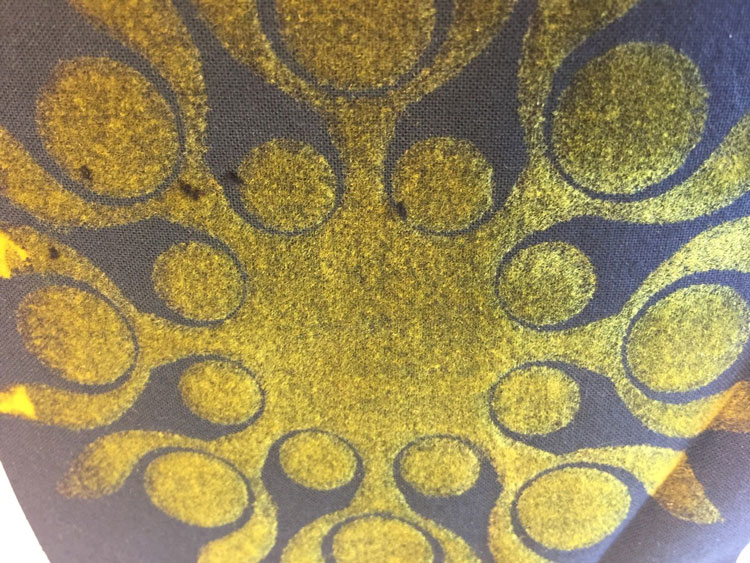

Flock printing

© University of Borås -

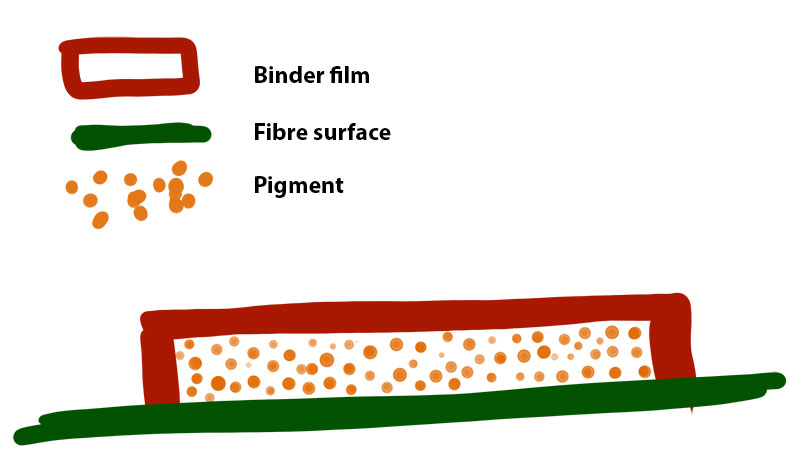

Pigment printing

Pigments are colour that are insoluble and do no penetrate into the fibres. Embedding the pigment colour with a film-forming binder.

Pigment printing

© University of Borås -

Warp printing

Printing the pattern onto the warp sheet before weaving.

Warp printing

© University of Borås -

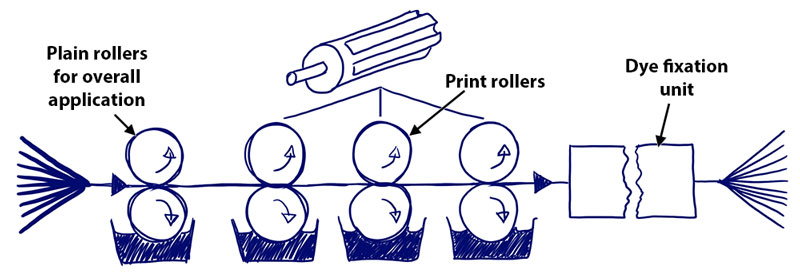

Roller printing

The oldest mechanised method of continuous printing. Printing the fabric with engraved metal roller with the printing design. One roller per colour in printing design

Roller printing (YouTube, 5:07)

-

Hand printing

The oldest method of printing. Applying the printing paste by means of a wooden block or by a stencil.

Block printing (YouTube, 5:29)

-

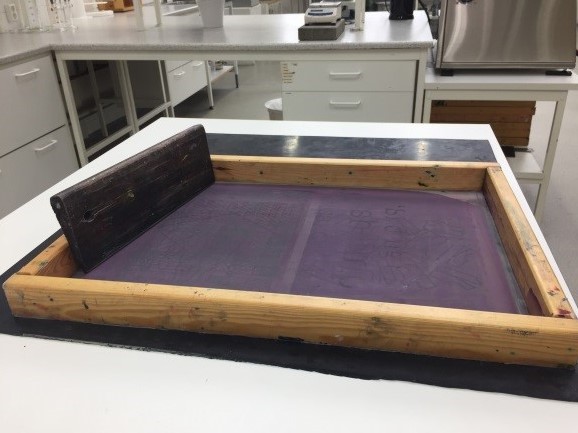

Screen printing

The most important printing method. Forming the design on a screen by blocking off those parts of the screen where no printing is to happen. Coating the screen with light-sensitive polymer and then selectively exposing through a stencil. Washing away the unexposed area (Exposed areas are made insoluble.)

Flat screen printing

- Holding the fabric firm and flat on a conveyor blanket.

- Supplying printing paste to the screens and forcing through the patterned areas by a squeegee roller or blade.

Flat bed screen printing (YouTube, 2:12)

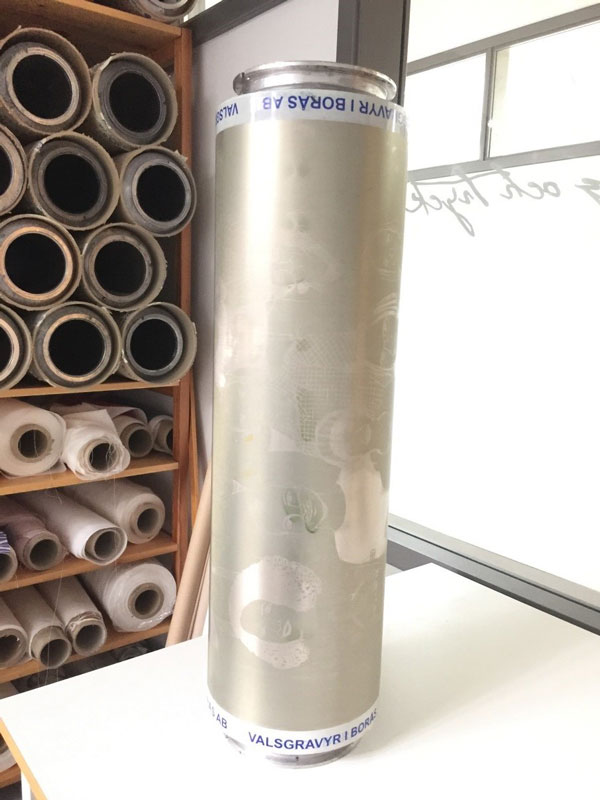

Rotary screen printing

- Continuous production.

- Pumping the printing paste from the reservoirs to the inside of the cylindrical screens.

Rotary screen printing (YouTube, 4:56)

Flat screen printing

© University of Borås

Rotary screen printing

© University of Borås

-

Project

Contact

This resource was developed as part of an Erasmus+ project, funded with support from the European Commission under grant agreement 2016-1-SE01-KA203-22064.

The project was a collaboration between:

- The University of Borås, Sweden

- The University of the Highlands and Islands, Scotland

- The University of Alcalá, Spain

- Digital Connections, Scotland

This resource has been released under Creative Commons license CC-BY-SA 4.0.

Disclaimer

If you would like more information on this resource please contact:

- Academic content – The University of Boras (www.hb.se)

- Technical resource development – The University of the Highlands and Islands Educational Development Unit - EDU (edu@uhi.ac.uk)

Except where otherwise noted, this website is licensed under Creative Commons license CC-BY-SA 4.0. All images used under permission remain the copyright of the license holder.

Download a copy of this resource in PDF format.

You can also print individual pages by printing directly from the browser.

-